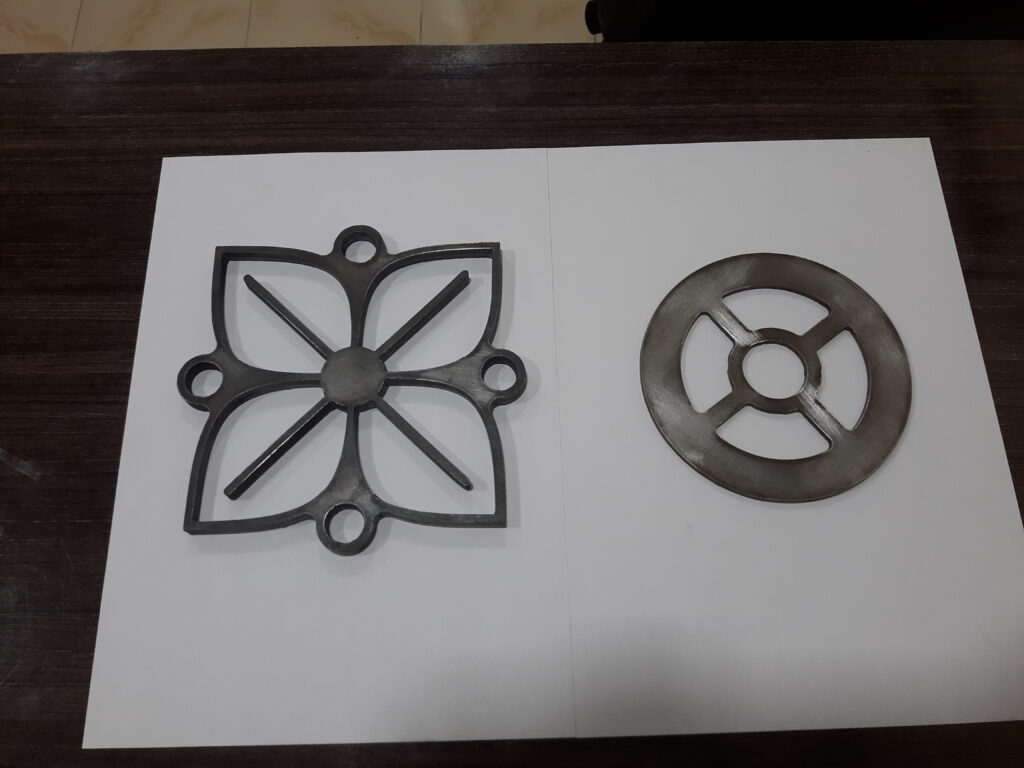

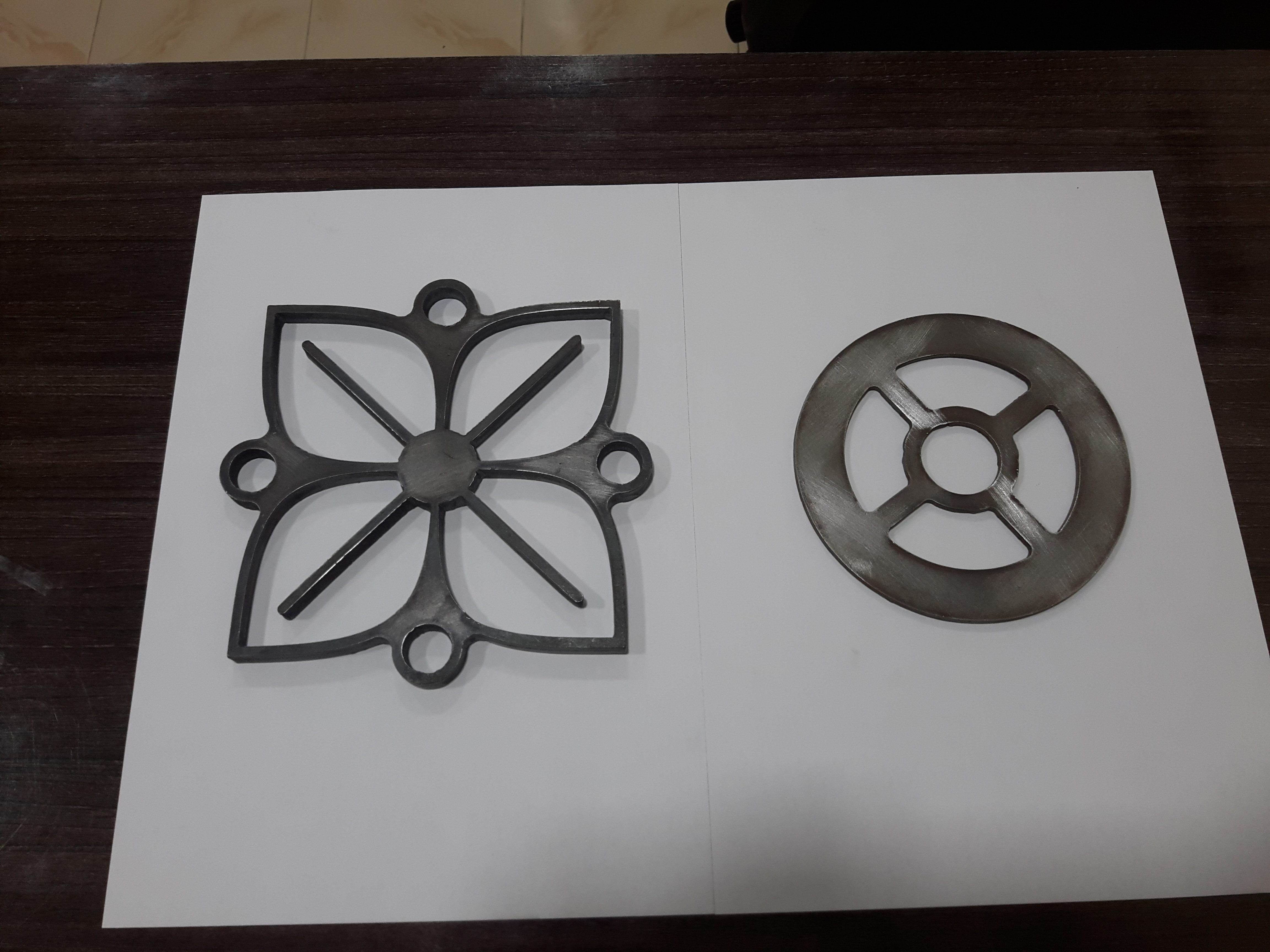

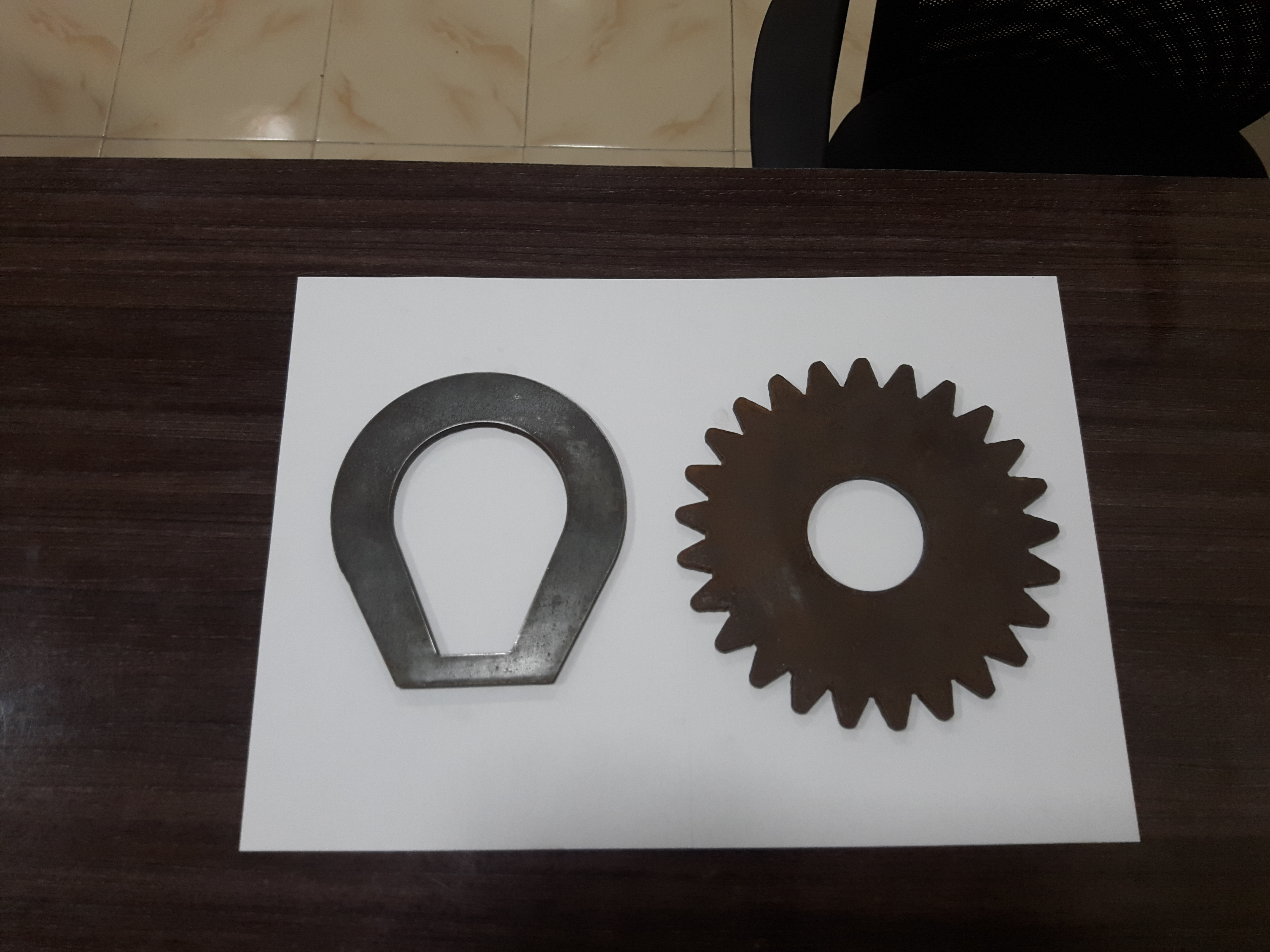

Profiles of thickness M.M => 0.5 to 50mm and S.S=> 0.5 to 80mm can be easily cut on our CNC Plasma Cutting Machine which is designed and manufactured by PROARC using high grade components while the bed size is 2500mm x 6300mm. The finishing quality of Job produced is very good.

Available Thickness (M.S.):- 5,6,8,10,12,14,16,18,20,22,25,28,30,32,36,40,45,50,56,63,70,80,90,100,110,120,130,140,150,160,170,180,190,200,220,260

Available Thickness (C-45.):- 20,25,30,32,36,40,45,50,56,63,70,80,90,100,110,120,130,140,150,160,180,190,200

CNC Plasma cutting machine is capable of cutting material much faster than oxy fuel, but plasma is only capable of piercing material up to 25mm thick. Plasma is also able to cut a larger range of material and transfers much less heat into material than oxy fuel. Often plasma cutting torches and oxy fuel cutting torches are mounted on the same CNC cutting machine to give the machine a larger range of processing thicknesses, for example 3mm – 150+mm. For most work Plasma is more efficient than Oxy fuel as 90% of steel cut is less than 50mm thick and if you were to compare some suitable Plasma Cutting system to an oxy fuel system it would process 50mm mild steel more than twice as fast.

This can be achieved by:

- Precision and Accuracy

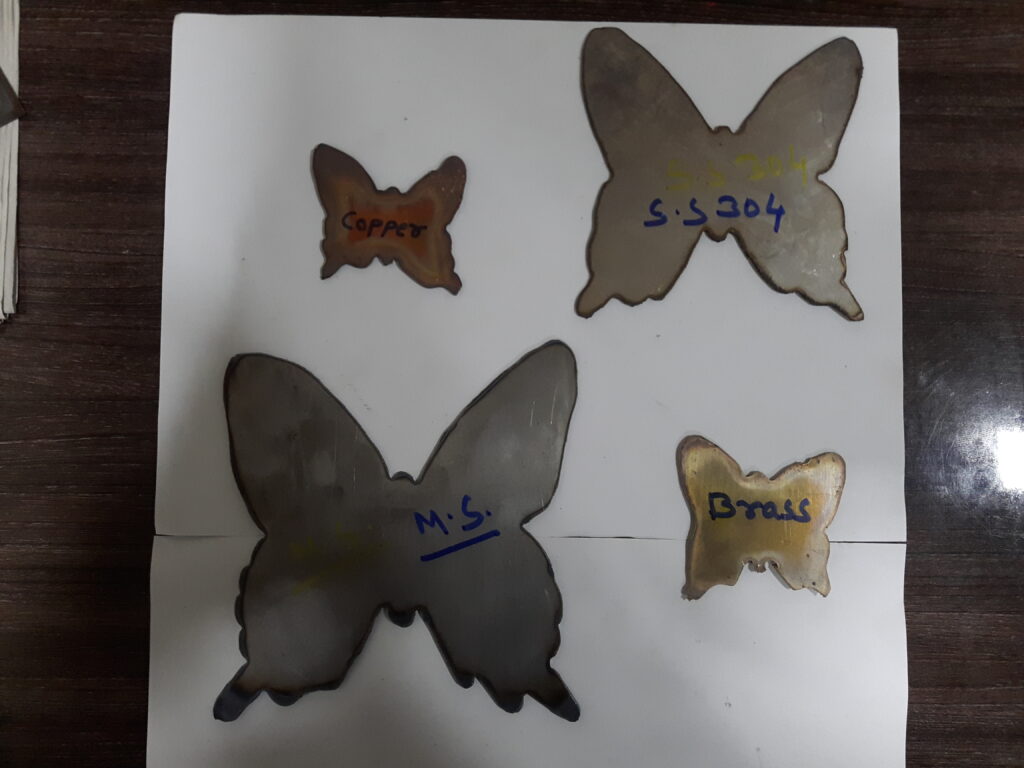

- Variety of materials

- Cost Effective

- Quick Operation

- Safe and Secure

- Working material: M.S , S.S , C-45 , Aluminium , Brass and Copper.

- Cutting thickness: 0.5 mm – 20 mm